Non Destructive

Get a Callback

Destructive testing is not always the choice as non-destructive testing is also needed after the construction of the structure. Non-destructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The main advantage of NDT is that the sample can be used even after the test. STH provides non-destructive testing facilities both at the laboratory as well as at onsite. STH provides the Non-destructive testing facilities to its clients and has following NDT testing facilities:

NDT Testing for Concrete

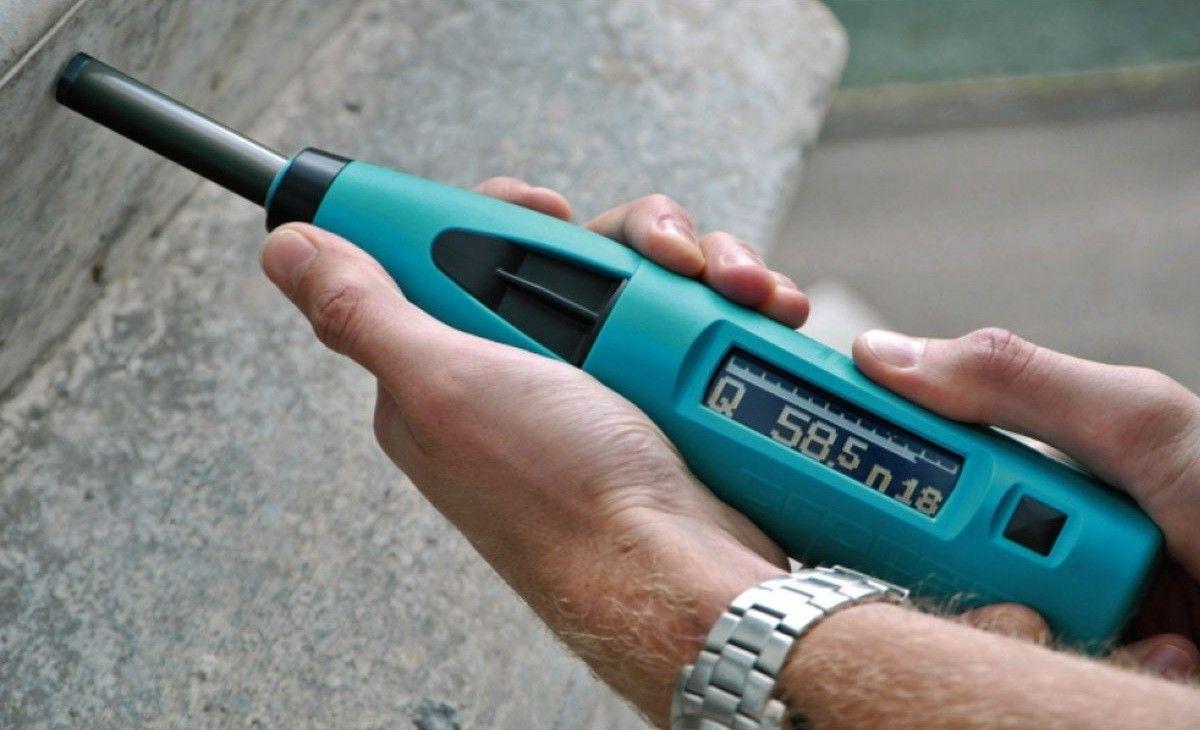

Rebound Hammer:

Rebound hammer test is done in order to find out the compressive strength of the concrete by using rebound hammer as per IS: 13311(part 2) – 1992.

Ultrasonic Pulse Velocity test

Ultrasonic pulse velocity is one of the methods of testing concreter on site. UPV test is conducted to determine the voids and cracks in the hardened concrete. It measures the time of the travel of an ultrasonic pulse passing through the concrete which is generated with the help of a pulse generator and is received by a pulse receiver. It is an ideal method for the ensuring that the concrete is uniform. STH provides facility for the onsite UPV test.

NDT Testing for Metal welding

Radiography:

This is an expensive technique compared to the other non-destructive techniques and is predominantly used to detect internal flaws in casting and weldments. This technique involves the use of penetrating gamma or X radiation to examine the parts and products for imperfections. Radiation is directed onto a film and possible imperfections are shown as the density changes in the film in the same manner as an X-ray shows broken bones. STH provides facility of radiography.

Services

- Non Destructive

- Industrial Chemical

- Fuel Testing

- Rubber and Polymer

- HDPE Pipe

- Water Testing

- Paper and Packaging Testing

- Automotive Part Testing

- ROHS Compliance

- Fertilizer

- Food Testing

- Environmental

- Textile Testing

- Soil and Geotechnical

- PVC Pipes

- Road Material

- Building Material

- Thermal Conductivity Testing

- Paint and Emus

- Metal and Alloy

- Electronics and Electrical