Cross-Linked Polyethylene (XLPE) insulated thermoplastic sheathed cables have become one of the most preferred choices for low-voltage power distribution. Their durability, strong electrical properties, and thermal performance allow them to work efficiently in demanding environments. For India’s industrial and infrastructure sectors, compliance with IS 7098 (Part-1):1988 + Amendments A1 to A5:2012 ensures that these cables meet strict quality and safety criteria.

Many industries today rely on certified XLPE insulated cables testing labs to verify performance, reliability, and long-term safety.

What Makes XLPE Insulated Cables Superior?

XLPE insulation is created by cross-linking polyethylene molecules, which significantly improves heat resistance, mechanical strength, and insulation stability. Unlike PVC insulation, XLPE does not soften under higher temperatures. It retains its shape and electrical properties even when exposed to overload or harsh environmental conditions.

For 1100V applications, this stability is critical. Industries need cables that can handle continuous electrical stress without degradation. Proper testing at an accredited 1100 volt power cables testing lab ensures that the cables meet the required standards.

Role of the IS 7098 (Part-1):1988 Standard

The IS 7098 Part 1:1988 standard defines essential construction parameters, insulation thickness, conductor quality, dielectric strength, and mechanical requirements for XLPE cables used up to 1100 volts.

The amendments A1 to A5:2012 updated the standard to reflect modern materials, improved safety techniques, and revised testing guidelines.

Manufacturers and engineers depend on an IS 7098 Part 1 1988 standard lab to check:

- Conductor resistance

- Insulation integrity

- High-voltage withstand performance

- Tensile and elongation strength

- Thermal aging properties

Only cables that successfully pass these tests can be certified for safe installation.

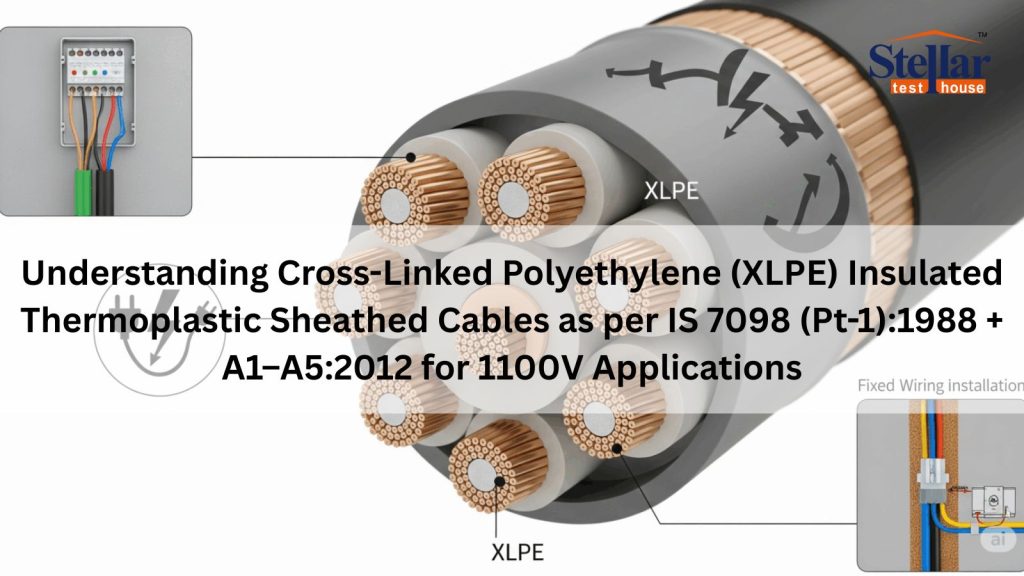

Construction of Thermoplastic Sheathed XLPE Cables

XLPE insulated thermoplastic sheathed cables are engineered to offer higher protection against moisture, chemicals, and mechanical stress. Their structure generally includes:

- High-conductivity aluminum or copper conductor

- XLPE insulation layer for thermal and electrical stability

- Inner sheath for bedding

- Armouring (optional) for mechanical protection

- Thermoplastic outer sheath for environmental resistance

Quality evaluation performed at a dedicated thermoplastic sheathed cables testing lab ensures that these layers work together to deliver reliable performance.

Why Compliance Matters for 1100V Installations

Any failure in a power cable can cause downtime, equipment damage, or safety hazards. That’s why industries in power distribution, building infrastructure, manufacturing, and utilities rely on proper testing before installation.

Regular inspections at cross-linked polyethylene wires testing labs help identify material inconsistencies, insulation defects, and early-stage deterioration.

Using IS-compliant cables ensures:

- Longer operational life

- Better heat resistance

- Improved short-circuit performance

- Enhanced safety for electrical systems

- Reduced maintenance costs

Where These Cables Are Commonly Used

XLPE insulated and thermoplastic sheathed cables are widely used in:

- Residential and commercial wiring

- Industrial power distribution networks

- Public utilities

- Control and instrumentation

- Underground and overhead electrical installations

- Renewable energy systems

Their flexibility and robustness make them suitable for both indoor and outdoor environments.

Additional XLPE Cable Testing Services

Industries searching for accurate and certified cable evaluation often look for:

- IS 7098 Certified XLPE 1100V Cable Testing Laboratory

- XLPE Thermoplastic 1100V Cables Testing as per IS 7098

- Reliable XLPE 1100V Cable Testing Lab – IS 7098 Compliant

- Cross-Linked Polyethylene 1100V Cable Testing Services

- IS 7098 Standard Testing for XLPE Insulated 1100V Cables

These specialized services ensure complete compliance with national standards and guarantee long-term operational safety.

Conclusion

Understanding the importance of Cross-Linked Polyethylene (XLPE) insulated thermoplastic sheathed cables and their compliance with IS 7098 (Pt-1):1988 + A1–A5:2012 is essential for safe and reliable power distribution. Thorough testing from certified labs—whether for XLPE insulated cables, 1100V power cables, or thermoplastic sheathed cables—ensures that each cable performs flawlessly under real-world electrical stresses.