In modern electrical systems, safety and reliability walk hand in hand. Whether it is in residential housing, industrial plants, or commercial complexes, the right choice of cable plays a vital role in both performance and protection. One area where standards and technology have come together for safer wiring solutions is in Halogen Free Flame Retardant (HFFR) cables. The Bureau of Indian Standards (BIS) has addressed this critical need through the standard (IS 17048:2018), which specifically covers the cable type (Halogen Free Flame Retardant – HFFR) designed for the voltage rating (up to 1100V).

This article explores what the standard means, why HFFR cables matter, and where they are commonly used. At Stellar Test House, we have closely worked with manufacturers and users to ensure that cables tested under this standard truly meet the safety benchmarks set by BIS.

Why Cable Standards Matter

Electric cables are more than just conductors; they are the lifelines of power distribution. Without well-defined standards, safety can easily be compromised. A faulty or poorly designed cable can overheat, emit toxic gases in case of fire, or fail under stress, leading to catastrophic incidents.

This is where the standard (IS 17048:2018) comes in. By laying down clear requirements for Halogen Free Flame Retardant (HFFR) cables, it ensures uniformity, safety, and quality across manufacturers and installations. Standards also give engineers, contractors, and end users the confidence that they are working with cables designed to protect lives and property.

Stellar Test House, as a recognized testing and certification facility, plays a crucial role in verifying compliance with this standard, ensuring that only safe and reliable cables reach the market.

What Makes HFFR Cables Special?

Traditional PVC cables, while widely used, release thick black smoke and toxic halogen gases when they catch fire. These gases can be corrosive and extremely dangerous for people trapped in enclosed spaces.

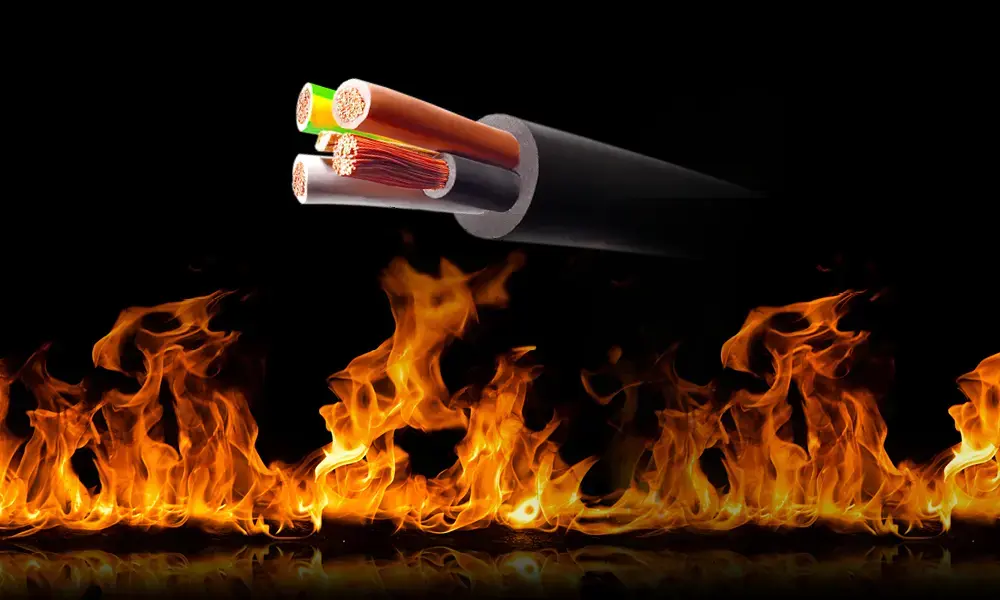

On the other hand, the cable type (Halogen Free Flame Retardant – HFFR) is engineered differently:

- Halogen Free: They do not release chlorine, fluorine, bromine, or iodine gases during combustion.

- Low Smoke Emission: In case of a fire, they emit much less smoke, ensuring better visibility for evacuation.

- Flame Retardant: They resist the spread of fire, confining it to a limited area instead of letting it run wild through an entire cable network.

At Stellar Test House, these properties are tested rigorously under controlled conditions to verify that every HFFR cable meets the safety promise it makes.

Understanding IS 17048:2018

So, what exactly does the standard (IS 17048:2018) specify? At its core, it provides the requirements for construction, insulation material, testing, and performance of HFFR cables used in electrical systems with the voltage rating (up to 1100V).

The standard covers aspects like:

- Conductor Material: Typically copper, ensuring excellent conductivity.

- Insulation Properties: Use of halogen-free compounds with high dielectric strength.

- Flame Retardancy Tests: Ensuring the cable does not propagate fire.

- Smoke Density and Gas Emission: Confirming that smoke is within acceptable limits and toxic gases are absent.

- Mechanical Strength: Verifying flexibility, tensile strength, and resistance to wear.

By following these guidelines, cable manufacturers can produce wires that are consistent in safety and performance. With testing support from facilities like Stellar Test House, compliance becomes more reliable and transparent for users and regulatory bodies alike.

Where Are HFFR Cables Used?

Because of their superior safety features, HFFR cables are widely preferred in areas where people gather in large numbers or where sensitive equipment must be protected. Some common applications include:

- Residential buildings and apartments – to protect families from smoke and toxic fumes in case of fire.

- Hospitals and healthcare facilities – where patient safety and equipment reliability are critical.

- Airports, railway stations, and metro systems – high-traffic zones that require maximum fire safety.

- Schools, colleges, and auditoriums – protecting students and staff in large enclosures.

- Industries and data centers – where equipment damage from corrosive gases can lead to massive financial losses.

- At Stellar Test House, we’ve seen a rising demand for testing of HFFR cables used in infrastructure projects, especially in metro cities where safety codes are becoming stricter.

Safety First

Beyond technical specifications, what really matters is human safety. Fires are unpredictable, and in most cases, it’s not the flames but the smoke and toxic gases that cause the most casualties. Imagine being trapped in a closed room during a fire: the difference between a PVC cable and an HFFR cable could mean the difference between life and death.

This is why the standard (IS 17048:2018) is not just another technical document. It represents a collective effort to prioritize human lives, reduce environmental impact, and promote safer electrical systems in India. With experienced testing partners like Stellar Test House, manufacturers and project owners can be confident that their products are not only compliant but also truly safe for real-world use.

Benefits at a Glance

To sum up, here are the key benefits of the cable type (Halogen Free Flame Retardant – HFFR) designed as per the standard (IS 17048:2018) for the voltage rating (up to 1100V):

- Enhanced fire safety through low flame spread.

- No emission of toxic halogen gases.

- Reduced smoke for safer evacuation.

- Protection of sensitive equipment from corrosive damage.

- Compliance with recognized safety standards, verified by testing facilities like Stellar Test House.

Conclusion

In today’s world, where electrical systems are everywhere, safety cannot be compromised. IS 17048:2018 provides a reliable framework for ensuring that Halogen Free Flame Retardant (HFFR) cables meet the highest standards of safety and performance. With their proven ability to resist fire, limit smoke, and eliminate toxic emissions, these cables are the smarter choice for modern infrastructure.

So the next time you think about wiring a building, upgrading an electrical system, or specifying cables for a project, remember: it’s not just about carrying current. It’s about protecting lives, property, and the future. And that’s exactly what the standard (IS 17048:2018) for HFFR cables with a voltage rating up to 1100V is all about.

At Stellar Test House, we are proud to contribute to this mission by testing and certifying cables that live up to the promise of safety, reliability, and trust.